Plant and Equipment Design:

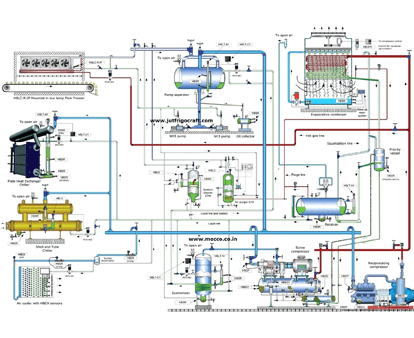

Drawings Services:

To be proposed based on Specific application suitability w.r.t. CAPEX, OPEX, Safety & environmental Analysis.

| R717 (Ammonia) | R22 | R23 | R134a |

| R290 (Propane) | R404a | R407c | R410a |

| R507 | R744 (CO2) | R1150 (Ethylene) | R1270 (Propylene) |

| …… and many more………. | |||

• Cold Storage Products like Vegetables, Fruits, Fish, Meat & dairy Products

• Frozen storage – Blast Freezers, Plate Freezers, Spiral Freezers etc.

• Water Cooling, Brine Cooling, Air Chilling, Process Gas or Fluid Cooling

• Thermal Design Calculations: For all types of Refrigerants by using proven Industry Standards and Software

• Thermal design of heat exchangers by using HTRI software for critical applications such as for petroleum and refinery applications

• Mechanical Design as per latest ASME, TEMA codes / IS / JIS / GEP (Good Engineering Practice)

• Mechanical design as per IBR requirements

• Pressure Vessels

• Sizing as per proven methods and Industry Standards

• Mechanical Design as per ASME code / GEP / All international codes

• Mechanical design as per IBR requirements

• Line Sizing

As per ASHRAE / GEP, Pressure drop calculations

• Heat pump and de-super heater

Heat pump and de-super heater / plant design for hot water (water temp. from 40 to 65 Deg.C) generation by using existing refrigeration system or by designing stand alone plant as heat pump.

• Oil Rectification System for maintaining Plant Design Capacity for flooded refrigeration plants such as Ammonia, propane, propylene refrigeration plants

• Air Purger System for saving operating power of the Plant for plants operating at very low temperatures and vaccum / negative operating pressure conditions.

• Adapting maintenance friendly Plant Layout

• Primary, Secondary and Tertiary Oil Separation to enhance oil separation up to 20 / 15 / 10 / 5 / 1 PPM for systems such as direct expansion refrigeration systems with refrigerants like R22, R134a, R404a, R407C etc. and for systems with chiller installation far away from compressor or condensing unit.

• Refrigeration plants for Cold Storage for various applications such as Dairy, meat, Fish, fruits, vegetable etc. cold storage of Modified Atmosphere (MA) and Controlled Atmosphere (CA) as per ASHRAE standards and working experience of around 20 years in this field

• Air conditioning plant design – heat load calculations & equipment / system design for office, laboratories, business complex, industries, hospital, air port, community centres etc. with green building concept design considerations

• Brine (Calcium Chloride, Ethylene Glycol, Propylene Glycol, Methanol, Ethanol or any other special fluid) Chilling Plants

• Water chilling plants – Direct expansion and flooded

• Air chilling plants

• Chlorine (Cl2) Liquefaction

• Carbon Dioxide (CO2) Liquefaction

• Acid chilling plants

• Refrigeration plants in Refinery and Petrochemical complexes as per American Petroleum Institute (API) standards and cooling / chilling application as required

• Refrigeration plants for Gas Compression, Storage / Handling systems as per American Petroleum Institute (API) standards

• Heat pump and de-superheater / plant design for hot water (water temp. from 40 to 65 Deg.C) generation by using existing refrigeration system or by designing stand alone plant as heat pump. Payback period from 2 to 5 years compared to traditional water heating plants / methods. Suitable for hotels, hospitals etc.

• ………. & many more applications as required

• Heat Transfer Research Inc. (HTRI) for Thermal design: Design approval by International and India's leading Engineering Consultants like Engineers India Ltd. (EIL, Delhi), UHDE India, Bechtel International, BechRel Engineering (Bechtel – Reliance JV) etc : 100% approvals

• Mechanical Design software as per ASME, TEMA & IBR codes: Design approval by International and India's leading Engineering Consultants like Engineers India Ltd. (EIL, Delhi), UHDE India, Bechtel International, BechRel Engineering (Bechtel – Reliance JV) etc : 100% approvals

• Structural Analysis by using STAD Pro software

• Piping Stress Analysis by using CEASER II Software tool and TRIFLEX program of Piping Solutions Inc, Houston, USA.

We value our customer's investments with our years of working experience with companies likes Johnson Controls / YORK / Frick-USA and Kirloskar Pneumatic. We are confident of meeting customer's requirements by best design practices, reliable material source, and an efficient project handling capability and most importantly with our institution for overall reliability.

• We are proud to be ONLY CONSULTANT in India with thorough design expertise of all types of compressors as referred above.

• Successfully designed about more than 700 refrigeration plants for various applications with low side temp. requirement as low as (-)105 Deg.C and up-to (+) 20 Deg.C using refrigerants like - Ammonia, R22, R-134a, R-23, R-32, R-404a, R-407C, R-507, R410a, R-1270 (Propylene), R-1150 (Ethylene), R-290 (Propane).

• We are helping other reputed refrigeration consultants like Forte Tekniks-Bhopal, S Subramanian – Nashik, Stratum Project Consultants – Bangalore along with many other small consultants and refrigeration contracting companies in their bottle-necks and critical design requirements.